On occasions RLU levels can be seen to increase after re-cleaning a surface. This mostly seen after a location has failed an ATP test and then as part of the corrective action process, is recleaned and then retested.

There are a number of reasons why RLU results can increase after recleaning.

- The second cleaning regime was inadequate and significant levels of organic contamination remain on the surface being tested.

- Cross-contamination has occurred e.g. User contaminated the swab with their hands in error or the cleaning tools e.g. Brushes / Cloths are contaminated

- The Cleaning Tools/ Chemicals used contain ATP

If the ATP test result increases after a cleaning treatment it can mean;

- Cross-contamination with ATP occurred during cleaning e.g. from a bare hand during the cleaning process (using a gloved hand can help to prevent this)

- The cleaning agent itself or cleaning materials contain ATP (this can happen with some paper towel or new microfibre cloths)

- Surface condition. The surface is porous and the act of cleaning releases engrained soil which will lift to the surface e.g. some food chopping boards and old or worn surfaces

Surface condition

Problems related to the surface condition are often found with older, worn, or damaged surfaces, and this can lead to a surface becoming uncleanable. ATP testing provides an effective and rapid means to monitor the surface condition and its degradation over time. Where this deterioration of equipment is found it may need renovation or replacing. While this is often seen on porous surfaces e.g. plastic or rubber materials such as used on conveyor belts, it manifests itself on harder surfaces that would be considered nonporous e.g. worn stainless steel surfaces, damaged and scratched plastic chopping boards which can exhibit similar problems.

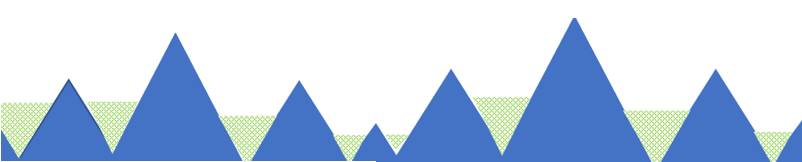

The basic diagram above shows a surface that has not been cleaned. The blue peaks represent the equipment surface at a microscopic level and the green represents organic contamination e.g. Food residue remaining after processing but before cleaning. The surface condition is poor and there are opportunities for product residues to be absorbed or embedded in the small crevices and surface scratches.

Test result = 60 RLU

The diagram above shows the same surface after cleaning. The majority of the surface contamination has been removed but some still remain trapped in the surface crevices. When tested there is still sufficient contamination to produce a high RLU / Fail result.

Test result = 120 RLU

The diagram above shows the same surface after recleaning. In this case the following second re-clean. The surface embedded contamination has been loosened and moved to the surface. When this is tested a fail RLU result again is likely and possibly higher than the original result, depending on the product and the surface condition

Where surfaces are of poor condition, they are difficult to clean effectively and may need more aggressive cleaning regimes. Surfaces can also provide a greater opportunity for the development of biofilm, scale, and niches for the growth of spoilage and pathogenic organisms.

The poor surface condition can show a number of effects on ATP results.

1 Resulting in increasing RLU results following successive cleans.

2 A number of repeat cleans required to reach an acceptable Pass RLU result (RLU values reducing slowly after successive cleans).

3 Variable and inconsistent RLU results over time – indicating cleaning is difficult to control at that location.

If you need any further support click on the icon below.